Manufacturer of Cleanroom Supplies

We believe in manufacturing innovative, cutting-edge cleanroom supplies that will lower your costs. We will provide you with products that perform better and are easier to use.

High-Tech Conversions, Inc. is a global manufacturer of cleanroom supplies and consumable items used in Controlled Environments, PCB Assembly Lines, Laboratories, and Manufacturing settings. Our line of cleanroom cleaning products includes custom and private label cleanroom supplies, ranges from cleanroom wipes and cleanroom gloves, sticky floor mats to disposable cleanroom garments and SMT cleaning rolls. Our focus is on providing high quality products that have been designed and manufactured to serve the exacting needs of our customers. Our company is continuously expanding and diversifying to meet the specifications for cleanroom supplies across a number of industries.

We are proud to offer a generous mix of in-stock cleanroom contamination control products, including cleanroom wipes, industrial wipes, cleanroom nitrile gloves, and a variety of other cleanroom consumables. Our line of Friendly Green environmentally friendly presaturated cleanroom wipes are a wonderful option for the eco-conscious business!

High-Tech Conversions understands that each manufacturing operation has its own standards for cleaning and contamination prevention products. To ensure that your specific needs are met, we can produce custom wipes, stencil rolls, gloves, garments, Tacky Traxx Mats, and a number other custom cleaning products. Our expertise also includes helping organizations choose products that meet USP guidelines with a variety of USP 797 / 800 Compliant Supplies.

With manufacturing facilities in the USA and China, we have the capacity and resources to handle custom converting & contract manufacturing orders using just about any fabric selection and a number of finishing options. High-Tech Conversions is proficient in converting and manufacturing products of non-woven materials, knits, wovens, paper and plastic film.

Contact us today to discuss the possibilities!

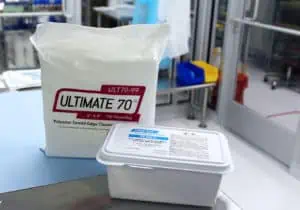

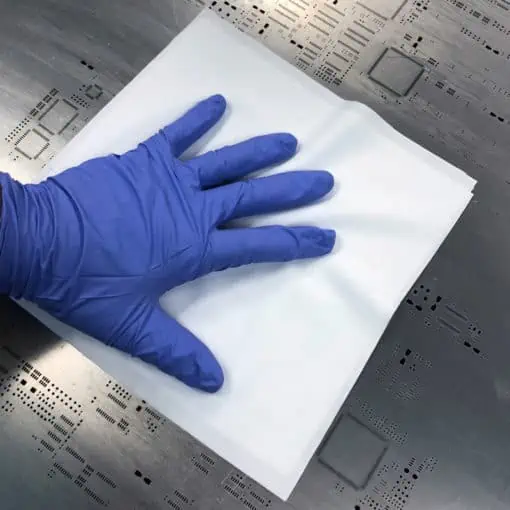

Wipes

Wipes for Cleanroom, Laboratory, Industrial, and Sterile Applications. Dry & Presaturated. Materials include Polyester, Nonwoven Poly-Cellulose, Cotton, and Microfiber. Custom and Private Label Options Available.

Browse All Wipes

Tacky Floor Mats

Sticky floor mats offered in a variety of colors and sizes. These multi-layered adhesive mats are designed to remove dirt and other particles from foot and wheel traffic upon entering a cleanroom. Custom logo & private label options Tacky Traxx Mats also available.

Browse All Tacky Floor Mats

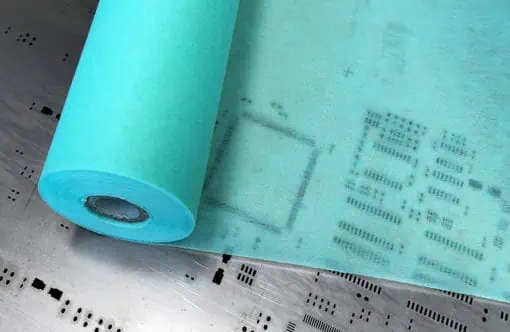

Stencil Wiping Rolls

ESD-Safe Green Monster Stencil Wiping Rolls for DEK, MPM (Speedline), FUJI, EKRA, and Panasonic SMT Printers. These rolls reduce damage to equipment, defects, bridges, blocked apertures, low transfer efficiency, and solder contamination

Browse All Green Monster Stencil Rolls

Cleanroom Garments

Aprons, Beard Covers, Bouffant Covers, Boot & Shoe Covers, Coveralls, Lab Coats, Facemasks, Sleeves, and Hoods. We stock protective apparel for a variety of cleanroom and industrial applications.

Browse All Cleanroom Garments

Disposable Gloves

Bee-Safe Class 100 Cleanroom Nitrile Gloves ideal for a variety of applications including Cleanroom, Lab, and Industrial. Available in 12″ length for extra protection.

Browse All Gloves

Tacky Rollers

Tacky Rollers are designed to remove particulate from flat and slightly textured surfaces within the cleanroom including floors, ceilings, and walls. Available in film or foam options.

Browse All Tacky RollersAlways Innovating

New Products

Cleaners & Alcohol

Cleanroom Gloves

Cleanroom Wiper Dispensers

From our blog

Latest News

Different Sources of Contamination within the Cleanroom

When it comes to maintaining the critical nature of a cleanroom, [...]

Read moreStoring and Handling Cleanroom Wipers: Your Complete Guide

Cleanrooms are imperative to a variety of industries where even a [...]

Read moreContamination Control in the Cannabis Industry: A Critical Role for Cleanrooms and Quality Air

In the rapidly evolving cannabis industry, contamination control has emerged as [...]

Read more